|

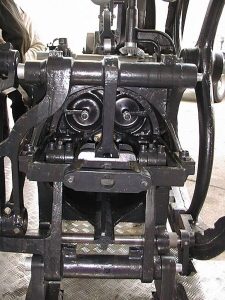

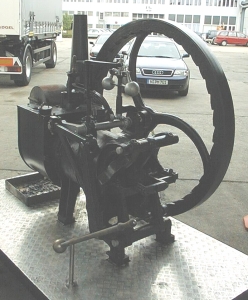

Flywheel Crank

The flywheel is dynamically balanced, see partially filled rim in

the picture to the left. In the static (stopped) state there is a considerable

imbalance, which is used to start the engine: Pumping the lever to the

right of the engine, the wheel can be turned easily to the upper dead center,

where the maximum heat is stored inside the displacer piston. From there

on the gravity turns the engine through half a cycle, up the point where

the heat meanwhile stored in the displacer is passed back to the new load

of air.

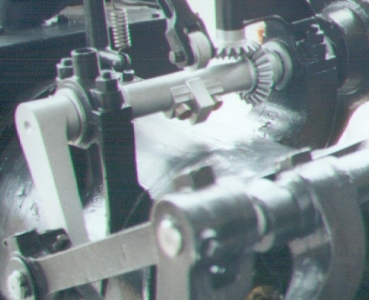

Crank

Lever Crank

Lever

|

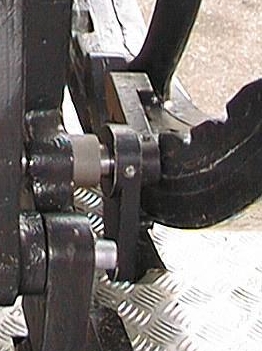

Crank Ratchet |

Ratchet teeth on flywheel |